Founded in 2015, Biron Teas (Macon, Ga.) sells organic artisanal teas through retail epicurean grocers, the hospitality industry and ecommerce.

Owners Andi and Roland Biron first relied on a Seattle-based co-packer to blend their tea varieties, but with cross country shipping fees, delays and growing demand, the company needed to expand capacity and bring blending in-house.

Mixing teas requires gentle handling. “Because our co-packer used a V-cone mixer, I looked at this equipment first,” said Andi Biron, but its swinging operation consumed too much floor space.

Biron ultimately specified a Rotary Batch MX-3-SS Mini Mixer from Munson Machinery for its smaller footprint and ability to produce uniform blends without product degradation or cross contamination. Established in 1823, Munson Machinery is a world leader in mixers, blenders and size reduction equipment for bulk solids materials. Munson offers 17 high-performance equipment lines, each with numerous models to meet specialized requirements in different industries, including tea.

Gentle Mixing Action, Short Cycles

Premium tea blends require special handling at each phase. The first step is to screen dust, twigs and foreign matter from the ingredients. “With chrysanthemum flowers, we want the blossoms but must remove the pebble-hard buds,” said Biron. “Ginger root also requires a thorough cleaning.”

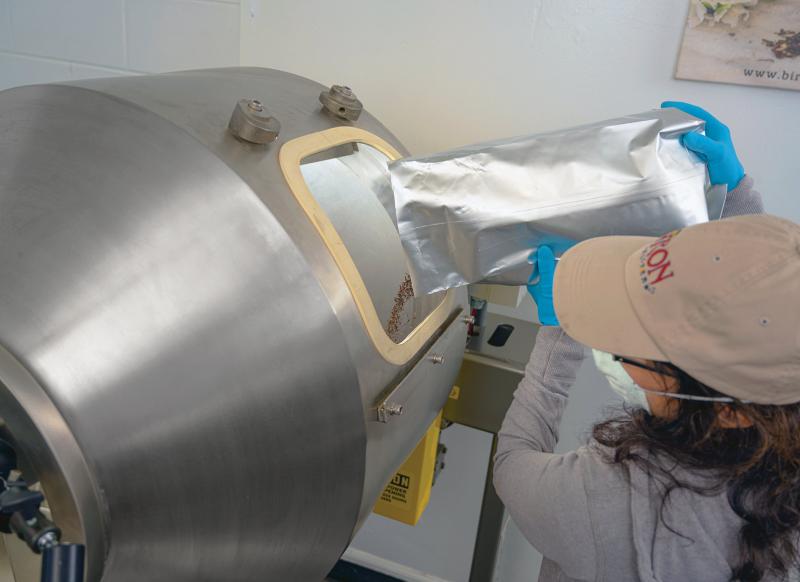

Proprietary combinations of herbs, florals, fruits and spices are loaded into the 3 cu ft (85 l) mixer, which is comprised of a stainless steel, horizontal drum having no internal shaft or shaft seals. Internal mixing flights impart a four-way mixing action that tumbles, folds, cuts and turns the material, causing particles to recombine 288 times per minute, with no shear or heat generation.

Natural oils and liquid flavors are metered through an integral stainless-steel spray line and pumped from a pressure pot on a scale for accurate liquid additions by weight.

Biron says the mixer blends 70 lb to 80 lb (32 to 36 kg) batches of tea blends with or without liquid additions uniformly in three minutes.

“Organic artisanal teas, especially blends with herbs, wild flowers, oils and berries, can’t be crushed or pulverized,” said Biron. “The mixer gently tumbles and turns a delicate – and sometimes sticky – tea mix into a uniform blend without pulverizing or powdering,” she said. The blending action prevents segregation of materials, regardless of size, shape or bulk density. “Chamomile and ginger can be especially difficult to mix,” said Biron, “but the mixer does the job, which is essential for uniform flavor.”

The mixer’s internal flights also serve to elevate and direct blended material through a discharge gate, with no residual or product waste.

“The mixer can be cleaned rapidly between blends,” said Biron. Because certain tea mixes incorporate natural flavors, oils and other ingredients that cling, selecting a mixer with a large drum access door for interior access was important.

Organic and Bio-Certified Packaging Supports Sustainability

Biron produces both traditional and unique artisanal tea blends. The organic certification of each ingredient and lot numbers are tracked and managed.

After blending, each special tea mix is scooped into a tea bagging machine, yielding about 20,000 bags per batch.

Biron tea bags are pyramid-shaped sachets made of Soilon woven mesh fiber made from corn starch that is certified as biodegradable. Biron Teas also selected recyclable biodegradable packaging for its hospitality product lines. “Our teas are organic and the overwraps are made from compostable biomaterial certified as bio-preferred by the U.S. Department of Agriculture,” she said. “We’re concerned about the planet and so are our customers.”

The company’s on-line products are packaged in decorative tins. “They have a greater lifecycle than paper since they can be recycled and reused over and over,” she says.

Mini Mixer Aids in Business Expansion

Thanks to booming sales and newfound mixing capacity, Biron Teas has expanded into co-packing and mixing for other tea purveyors. “When you are blending 70 to 80 lb (32 to 36 kg) of tea, there is no way that can be done in a commercial kitchen with stainless steel mixing bowls,” says Biron. “I love the idea that we can help other artisan tea makers grow, too.”

To learn more about Biron Teas, visit BironTeas.com. To learn more about Munson Machinery Company, Inc., visit Munson Machinery.com.